1. Introduzzjoni

This manual provides essential instructions for the safe and efficient operation, setup, and maintenance of your SainSmart Genmitsu 3020-PRO Ultra CNC Router Machine. Please read this manual thoroughly before using the machine to ensure proper functionality and to prevent damage or injury.

Image: The SainSmart Genmitsu 3020-PRO Ultra CNC Router Machine, showcasing its capabilities with carved wood and metal samples.

2. Informazzjoni dwar is-Sigurtà

Always prioritize safety when operating the CNC router. Failure to follow safety guidelines can result in serious injury or damage to the equipment.

- Tagħmir Protettiv Personali (PPE): Always wear safety glasses or a face shield to protect against flying debris. Consider hearing protection, especially during prolonged operation.

- Żona tax-Xogħol: Ensure your work area is clean, well-lit, and free from obstructions. Keep children and unauthorized personnel away from the machine during operation.

- Assigurazzjoni tal-Materjal: Dejjem sew clamp your workpiece to the spoilboard to prevent movement during carving. Loose material can cause tool breakage and machine damage.

- Għodda: Use sharp, appropriate tooling for the material being cut. Dull or incorrect tools can lead to poor results, excessive force, and potential hazards.

- Waqfien ta' Emerġenza: Iffamiljarizza ruħek mal-post u t-tħaddim tal-buttuna ta' waqfien ta' emerġenza.

- Skonnettjar tal-Enerġija: Disconnect power to the machine before performing any maintenance, adjustments, or tool changes.

- Ventilazzjoni: Ensure adequate ventilation, especially when cutting materials that produce dust or fumes.

3. Setup

3.1 Żpakkjar u Spezzjoni Inizjali

Carefully unpack all components and verify against the packing list. Inspect for any shipping damage. If any components are missing or damaged, contact customer support immediately.

3.2 Assemblea

The SainSmart Genmitsu 3020-PRO Ultra is designed for quick assembly, typically within 15 minutes, as many components come pre-assembled.

Immaġni: Sploda view diagram illustrating the simple, pre-assembled nature of the Genmitsu 3020-PRO Ultra, emphasizing its quick 15-minute assembly.

- Place the main frame on a stable, level surface.

- Attach any remaining pre-assembled modules as per the included quick-start guide.

- Connect all cables securely, ensuring they are not pinched or strained.

3.3 Installazzjoni tas-Sewwieq u s-Softwer

To operate the CNC machine, you will need to install the necessary drivers and control software. The machine typically uses Candle software for control.

- Insert the provided TF card (or USB drive) into your computer.

- Locate and install the drivers for your operating system.

- Open the Candle software executable from the TF card.

Video: A tutorial demonstrating how to install drivers, open Candle software, and perform basic operations like jogging and setting the work origin. This video is provided by SainSmart Official.

4. Istruzzjonijiet Operattivi

4.1 Basic Controls (Jogging)

Once Candle software is open and connected to your machine, you can manually move the spindle using the jogging controls.

- Use the blue arrow buttons to move the X-axis (left/right) and Y-axis (forward/backward).

- Use the white arrow buttons to move the Z-axis (up/down).

- Aġġusta l- Pass value to control the distance of each movement. A larger step value results in greater movement.

- Aġġusta l- Għalf value to control the speed of movement. A higher feed value results in faster movement.

4.2 Loading G-Code

G-kodiċi files contain the instructions for the CNC machine to carve your design.

- In Candle, go to File > Iftaħ.

- Navigate to your G-code file (e.g., .nc, .gcode) and open it.

- Observe the origin position of the G-code in the software's preview to understand where the project's origin is set relative to your material.

4.3 Setting Work Origin (Zeroing)

Setting the work origin is crucial for accurate carving. This tells the machine where the (0,0,0) point of your material is.

- Manually jog the spindle using the controls until the tip of your carving bit is positioned at the desired X and Y origin point on your workpiece.

- Lower the Z-axis until the bit just touches the surface of your material.

- In Candle, click the ZERO XY button to set the X and Y origin.

- Ikklikkja l- ZERO Z button to set the Z origin.

4.4 Starting a Project

Once the G-code is loaded and the work origin is set, you can begin carving.

- Kun żgur li l-biċċa tax-xogħol tiegħek hija mwaħħla sewamped and the area is clear.

- Ikklikkja l- Ibgħat button in Candle to start the carving process.

- Monitor the machine during operation. Be prepared to use the emergency stop if any issues arise.

Immaġni: Close-up view of the Genmitsu 3020-PRO Ultra CNC router carving into an aluminum block, demonstrating its capability to achieve a 1.5mm cut depth in a single pass.

Image: A carved wooden piece demonstrating the high precision and detailed results achievable with the CNC router.

5. Manutenzjoni

Manutenzjoni regolari tiżgura l-lonġevità u l-prestazzjoni ottimali tar-router CNC tiegħek.

- Tindif: After each use, clean the machine thoroughly to remove dust, chips, and debris. Use a vacuum cleaner or compressed air. Avoid using liquids directly on electronic components.

- Lubrikazzjoni: Periodically lubricate the lead screws and linear rails with appropriate grease or oil to ensure smooth movement. Refer to the manufacturer's recommendations for specific lubricants.

- Verifika tal-Issikkar: Regularly check all screws, bolts, and connections for tightness. Vibrations during operation can cause fasteners to loosen over time.

- Kura tal-magħżel: Inspect the spindle and collet for wear or damage. Ensure the collet is clean and free of debris before inserting a bit.

- Ġestjoni tal-Kejbil: Ensure all cables are properly routed and secured to prevent snagging or damage.

6 Issolvi l-problemi

Din it-taqsima tindirizza kwistjonijiet komuni li tista’ tiltaqa’ magħhom.

- Machine Not Connecting:

- Ensure USB cable is securely connected to both the machine and computer.

- Verify that the correct drivers are installed and the software is configured for the correct COM port.

- Restart the software and the machine.

- Motors Not Moving:

- Check power supply connection to the machine.

- Ensure emergency stop button is not engaged.

- Verify motor cables are securely connected.

- Poor Carving Quality:

- Check if the carving bit is sharp and appropriate for the material.

- Kun żgur li l-biċċa tax-xogħol tkun clamped.

- Adjust feed rates and depth of cut in your G-code generation software.

- Check for loose components or excessive play in the machine's axes.

- Il-magħżel mhux qed idur:

- Check spindle power connection.

- Ensure the spindle is enabled in the control software.

- Verify spindle speed settings.

7. Speċifikazzjonijiet

Key technical specifications for the SainSmart Genmitsu 3020-PRO Ultra CNC Router Machine:

| Karatteristika | Speċifikazzjoni |

|---|---|

| Brand | SainSmart |

| Numru tal-Mudell | 3020PU |

| Materjal | Metall |

| Sors tal-Enerġija | Corded Elettriku |

| Dimensjonijiet tal-Prodott | 11.8"W x 3.1"H (Work Area: 11.8"x8.1"x3.1") |

| Voltage | 230 Volts |

| Piż tal-oġġett | 15.3 Kilogrammi (33.7 libbra) |

| Veloċità ta' Rotazzjoni Massima | 30000 RPM |

| Qawwa tal-magħżel | 710W |

| Muturi Stepper | 60mm, 7.3 Nm torque (XYZ-axis) |

| Spindle Collet | 1/8" ER11 |

| Ħin tal-Assemblea | Approx. 15 minutes (pre-assembled) |

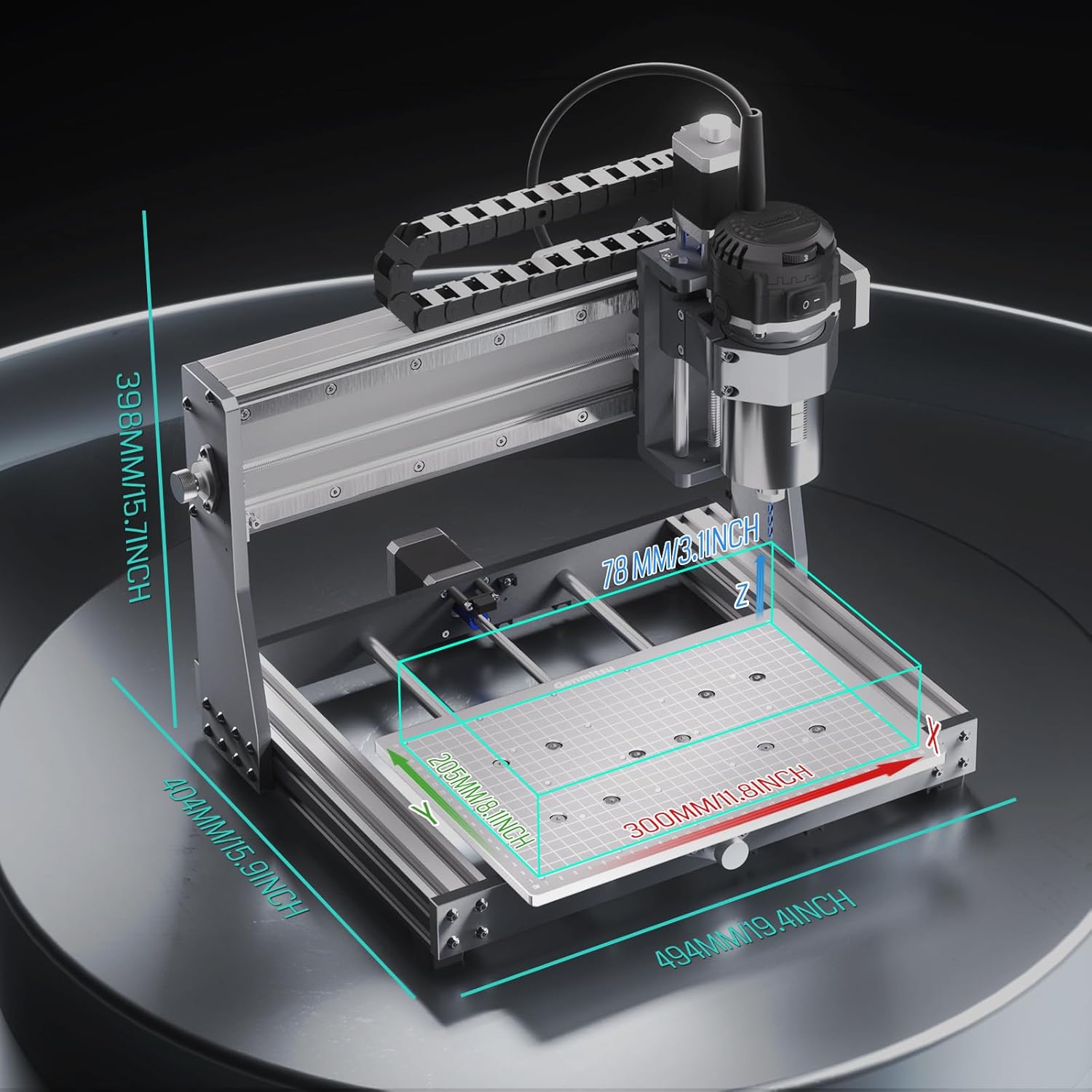

Image: A detailed diagram illustrating the physical dimensions and work area of the Genmitsu 3020-PRO Ultra CNC Router Machine.

Image: A close-up of the upgraded 60mm NEMA17 stepper motors for the XYZ-axis, highlighting their 7.3 N.m torque for enhanced cutting power.

Image: A detailed diagram of the 710W spindle motor, showing its adjustable speed range (6500-30000 RPM), ON/OFF switch, and ER-11 collet.

Image: A diagram illustrating the wide spindle compatibility of the machine, showing options for a Φ65mm compact router, Φ69mm trim router (with separate holder), and a laser module.

8. Informazzjoni dwar Garanzija

SainSmart products typically come with a manufacturer's warranty covering defects in materials and workmanship. For specific warranty terms, duration, and claim procedures, please refer to the warranty card included with your product or visit the official SainSmart websit. Żomm il-prova tax-xiri tiegħek għal talbiet ta' garanzija.

9. Appoġġ għall-Klijent

If you encounter any issues not covered in this manual, require technical assistance, or have questions regarding your SainSmart Genmitsu 3020-PRO Ultra CNC Router Machine, please contact SainSmart customer support. You can typically find contact information on the official SainSmart webis-sit jew permezz tal-bejjiegħ bl-imnut minn fejn xtrajt il-prodott.

Riżorsi onlajn:

- Żur il- SainSmart Store on Amazon għal informazzjoni dwar il-prodott u aċċessorji.

- Check the official SainSmart website for updated manuals, FAQs, and community forums.