1. Introduzzjoni

This manual provides detailed instructions for the safe and effective operation, maintenance, and troubleshooting of your VTSYIQI Ultrasonic Hardness Tester Meter. This instrument is designed for direct measurement of Vickers hardness values, eliminating the need for conversion from other hardness scales and thereby reducing potential conversion errors. It offers high test speed, producing results within seconds, and creates a standard Vickers indentation with minimal damage to the workpiece. Please read this manual thoroughly before using the device.

2. Prodott Aktarview

2.1 Komponenti

The VTSYIQI Ultrasonic Hardness Tester Meter consists of the main host unit, a probe, and connecting cables. Key interfaces include a USB port for charging and data transfer, and an eight-core socket for probe connection.

Figura 2.1: VTSYIQI Ultrasonic Hardness Tester Meter with labeled components. This image displays the main host, probe, probe connection cable, charge lamp, USB interface, and eight-core socket, indicating their positions on the device.

2.2 Karatteristiċi ewlenin

- Direct Vickers Hardness Measurement: Eliminates conversion errors from other scales.

- High Test Speed: Provides results within seconds.

- Minimal Workpiece Damage: Standard Vickers indentation is tiny.

- Multi-point Calibration Mode: Essential for new or composite materials.

- Display bil-kulur: For clear readability of measurements and settings.

- Batterija fit-tul: Equipped with a 3000mA lithium battery.

- Ħażna tad-Data: Jaħżen sa 50 grupp ta' dejta tal-kejl.

- Konnettività Bluetooth: For external data printing and export.

- Disinn portabbli: Small volume, light weight, and easy to carry for on-site testing.

- Applikazzjoni versatili: Suitable for small forgings, foundry materials, weld inspection, and difficult-to-access areas like gear teeth.

Figura 2.2: Multiple functions of the VTSYIQI Ultrasonic Hardness Tester. This image highlights features such as one-point and multi-point calibration, various hardness scales (HRC, HRB, HRA, HB, HV), color LCD screen, 3000mA lithium battery, 360° test support, 50 sets of data storage, Bluetooth connection, small test indentation, and fast measurement speed. It also lists compliance with several industry standards.

3. Setup

3.1 Spakkjar u Spezzjoni

- Carefully unpack all components from the carrying case.

- Verify that all items listed in the packing list are present and undamaged. The typical package includes the main host, probe, connection cables, charger, and a calibration block.

- Report any missing or damaged items to your supplier immediately.

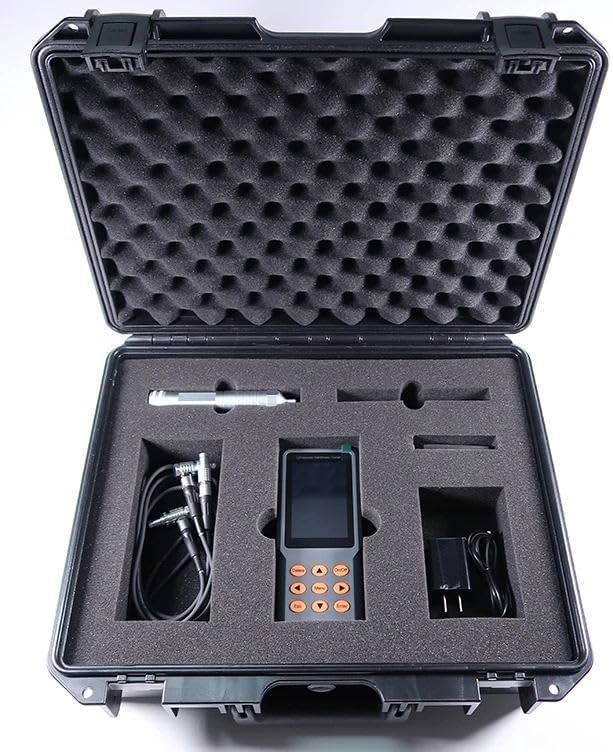

Figura 3.1: Contents of the VTSYIQI Ultrasonic Hardness Tester Meter package. This image shows the main host unit, probe, connecting cables, charger, and a small calibration block neatly arranged within a protective carrying case.

3.2 Konnessjoni tas-Sonda

Connect the probe cable to the eight-core socket on the main host unit. Ensure the connection is secure to prevent measurement inaccuracies.

3.3 Ixgħel u Iċċarġja

- Agħfas u żomm il- Mixgħul/Mitfi buttuna biex tixgħel l-apparat.

- If the battery is low, connect the charger to the USB interface. The charge lamp se jindika l-istatus tal-iċċarġjar.

- Allow the device to fully charge before initial use for optimal battery life.

Figura 3.2: VTSYIQI Ultrasonic Hardness Tester Meter ready for operation. This image shows the main unit and its connected probe, illustrating the device in a ready-to-use configuration.

4. Operazzjoni

4.1 Kejl Bażiku

- Mill-menù prinċipali, mur fuq Meas Setup.

- Select the appropriate material type for your workpiece. The test results are related to the elastic constants of the workpiece.

- Ensure the workpiece surface has a maximum roughness of Ra<15μm and a minimum thickness of 2mm. The minimum workpiece weight should be 0.3kg.

- Place the probe firmly and perpendicularly onto the test surface.

- Initiate the measurement as per the on-screen instructions. The device will output the Vickers hardness value within seconds.

- Read the displayed hardness value.

Figura 4.1: Ultrasonic Hardness Tester in use. This image shows the device with its probe applied to a material, demonstrating the process of taking a hardness measurement. The main menu is visible on the screen.

4.2 Kalibrazzjoni

For new materials or composites, calibration is crucial to ensure accurate readings. The device supports multi-point calibration.

- Aċċess għall- Materjal or Sistema menu to find calibration options.

- Follow the on-screen prompts to perform a multi-point calibration using a known reference block for the specific material.

- The device allows direct testing with multi-point calibration, eliminating the need for a hardness conversion table for new materials.

Figura 4.2: Multi-point calibration mode. This image shows the device display with options for various hardness scales (HL, HB, HV, HS, HRA, HRB, HRC), indicating the device's capability for multi-point calibration across different material types.

4.3 Ġestjoni tad-Data

The device can store up to 50 groups of measurement data. You can access stored data via the Ħażna menu.

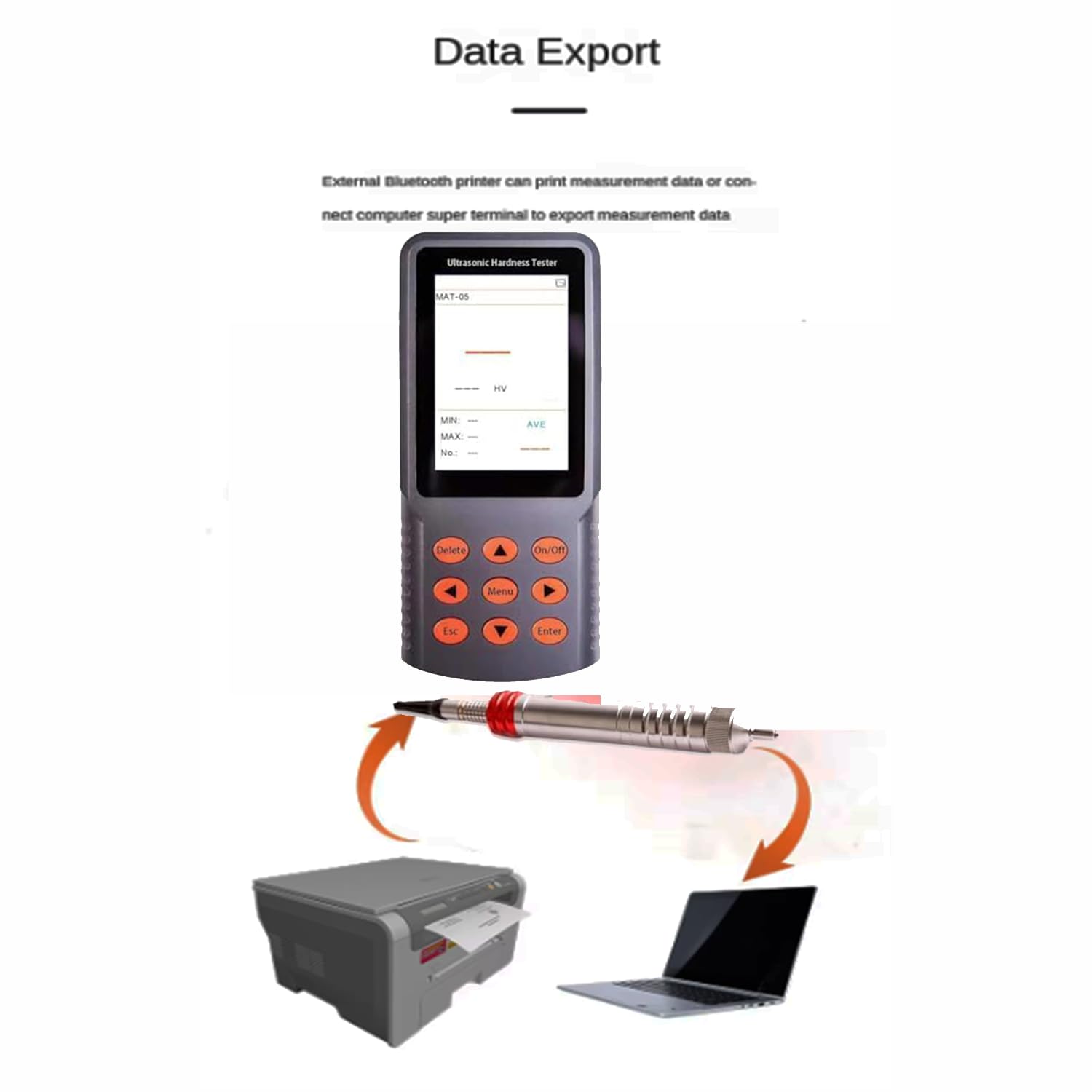

- Esportazzjoni tad-Dejta: Measurement data can be exported to an external Bluetooth printer for immediate hard copies or connected to a computer via USB for detailed analysis and record-keeping.

Figura 4.3: Data export functionality. This image illustrates the device's ability to export data, showing it connected to both a printer and a laptop, signifying options for printing or digital transfer of measurement results.

4.4 Operation Video

Vidjo 4.1: Ultrasonic Hardness Meter Operation. This video provides a brief demonstration of the VTSYIQI Ultrasonic Hardness Tester Meter in operation, showcasing how to use the device for hardness measurements.

5. Manutenzjoni

5.1 Tindif

- Regularly clean the main unit and probe with a soft, dry cloth.

- Do not use abrasive cleaners or solvents, as these can damage the device's surface or internal components.

- Ensure the probe tip is free from debris before each measurement to maintain accuracy.

5.2 Kura tal-Batterija

- Iċċarġja l-apparat regolarment, anke jekk ma jintużax ta' spiss, biex iżżomm il-batterija f'kundizzjoni tajba.

- Evita li tiċċarġja l-batterija kompletament ta' spiss.

- Aħżen l-apparat f'post frisk u niexef meta ma jkunx qed jintuża.

5.3 Ħażna

When not in use, store the hardness tester and its accessories in the provided protective carrying case to prevent damage from dust, moisture, and impact.

6 Issolvi l-problemi

Din it-taqsima tindirizza kwistjonijiet komuni li tista' tiltaqa' magħhom mat-tagħmir tiegħek.

6.1 L-Apparat Mhux Qed Jixgħel

- Iċċekkja l-batterija: Ensure the battery is sufficiently charged. Connect the charger and allow it to charge for at least 30 minutes before attempting to power on again.

- Buttuna tal-Qawwa: Confirm the On/Off button is pressed and held correctly.

6.2 Inaccurate or Inconsistent Readings

- Konnessjoni tas-Sonda: Verify the probe is securely connected to the main unit.

- Tip tas-sonda: Inspect the probe tip for wear or damage. A worn tip can affect accuracy.

- Workpiece Surface: Ensure the test surface is clean, smooth (Ra<15μm), and flat.

- Għażla tal-Materjal: Confirm the correct material type is selected in the device settings.

- Kalibrazzjoni: Perform a multi-point calibration, especially if testing a new material or if results are consistently off.

- Workpiece Size: Ensure the workpiece meets the minimum requirements (thickness > 2mm, weight > 0.3kg).

6.3 Data Export Issues

- Konnessjoni Bluetooth: Ensure Bluetooth is enabled on both the tester and the external device (printer/computer) and that they are properly paired.

- Konnessjoni USB: Verify the USB cable is correctly connected and that the computer recognizes the device.

7. Speċifikazzjonijiet

| Karatteristika | Speċifikazzjoni |

|---|---|

| Numru tal-Mudell | VTSYIQI20241203140278954VTSYIQI |

| Tip ta' Sonda | 10kgf Manual Probe |

| Forza tat-Test | 98N |

| Dijametru tas-Sonda | 22mm |

| Tul tas-Sonda | 150mm |

| Resonating Rod Diameter | 2.4mm |

| Max. Surface Roughness | Ra < 15μm |

| Min. Workpiece Weight | 0.3kg |

| Min. Workpiece Thickness | 2mm |

| Batterija | Batterija tal-litju 3000mA |

| Dimensjonijiet tal-Prodott | 5.91 x 1.97 x 9.84 pulzieri |

| Piż tal-Prodott | 8.82 Liri |

8. Garanzija u Appoġġ

For warranty information, please refer to the documentation provided at the time of purchase. If you require technical assistance, troubleshooting beyond this manual, or have questions regarding your VTSYIQI Ultrasonic Hardness Tester Meter, please contact the manufacturer or your authorized dealer for support.