1. Introduzzjoni

Welcome to the user manual for your IKIER K1 Pro Max 70W Laser Engraving Machine. This powerful and versatile machine is designed for high-precision engraving and cutting across a wide range of materials, including wood, acrylic, metal, and leather. This manual provides essential information for safe operation, setup, maintenance, and troubleshooting to ensure you get the most out of your device.

Jekk jogħġbok aqra dan il-manwal bir-reqqa qabel ma tħaddem il-magna u żommu għal referenza futura.

2. Informazzjoni dwar is-Sigurtà

WARNING: Laser radiation can cause eye damage and skin burns. Always wear appropriate laser safety goggles when operating the machine. Never look directly into the laser beam.

- Protezzjoni tal-għajnejn: Always wear certified laser safety goggles (OD6+) when the machine is in operation.

- Ventilazzjoni: Ensure adequate ventilation in your workspace to dissipate fumes and smoke produced during engraving and cutting. Some materials can produce toxic fumes.

- Periklu tan-Nar: Laser processing can ignite flammable materials. Always have a fire extinguisher readily available. Never leave the machine unattended during operation.

- Sigurtà tal-Materjal: Only process materials suitable for laser engraving/cutting. Avoid materials that produce hazardous gases or can easily ignite.

- Waqfien ta' Emerġenza: Familiarize yourself with the physical emergency stop switch.

- Lock tat-tfal: Utilize the child lock feature to prevent unauthorized use.

- Sejbien tal-Fjamma: The machine is equipped with flame detection. If a flame is detected, the machine will automatically stop.

- Sejbien tal-inklinazzjoni: The machine features tilt detection for added safety. If the machine is tilted during operation, it will stop.

Figure 2.1: Comprehensive safety features of the IKIER K1 Pro Max, including child lock, flame detection, and tilt detection, designed to ensure secure operation.

3. Prodott Aktarview

The IKIER K1 Pro Max is a state-of-the-art 70W laser engraving and cutting machine, engineered for precision and efficiency. It features a robust design with advanced functionalities to enhance your creative and production capabilities.

Figure 3.1: The IKIER K1 Pro Max 70W Laser Engraving Machine, showcasing its main components including the laser module and external air assist unit.

Karatteristiċi ewlenin:

- Powerful 70W Laser Output: Equipped with 14x6W laser diodes, providing exceptional cutting and engraving power, capable of cutting 25mm plywood in a single pass.

- Intelligent Z-Axis: Features both electric and manual settings, enabling automatic focus adjustment in approximately 8 seconds for precise laser positioning.

- Intelligent Air Assist: Integrated double-layer design ensures continuous airflow, preventing blockages and improving cutting performance.

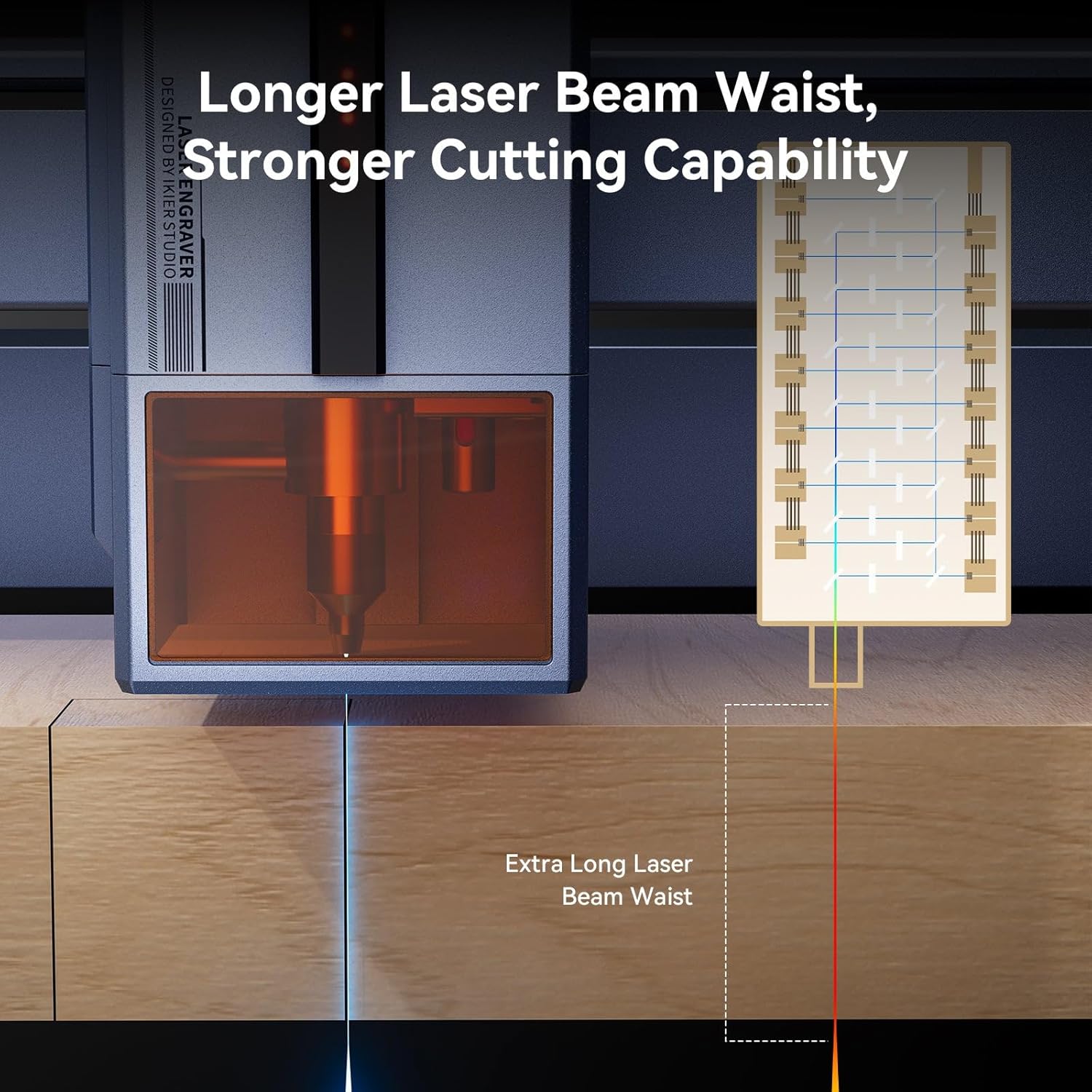

- Sinking Cut Technology: Optimized laser algorithm and intelligent motherboard control automatic laser origin, increasing cutting depth by 30-50%.

- Skrin tat-Touch LCD ta' 4.3 pulzier: Allows for convenient offline operation, freeing the machine from constant computer connection.

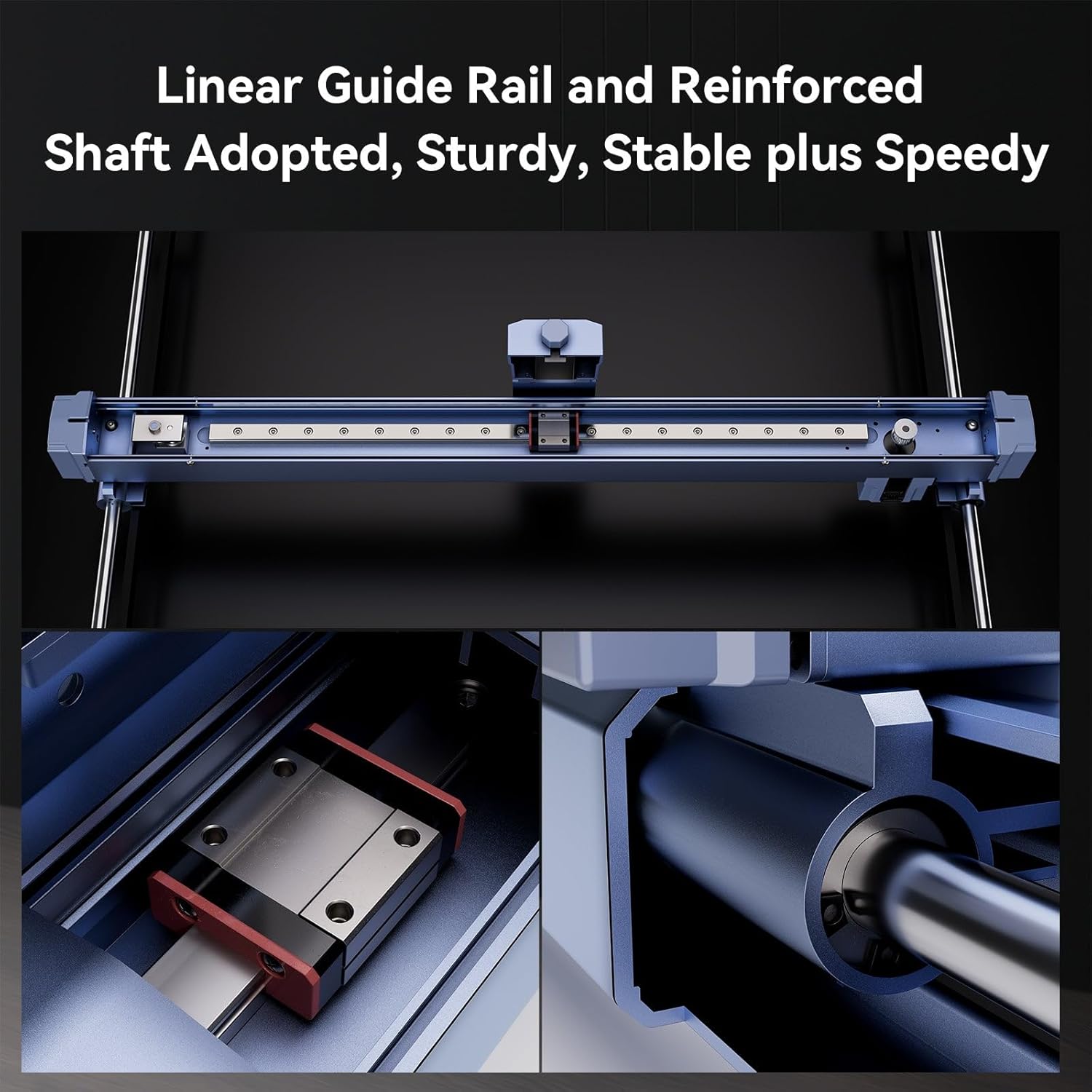

- Kostruzzjoni robusta: Utilizes an optical axis and linear guide structure for enhanced stability, precision, and speed.

- Cross Positioning System: Provides precise and horizontal output for accurate engraving alignment and observable framing.

Figura 3.2: Dettaljat view of the laser module, illustrating the arrangement of multiple 6W laser diodes that combine to achieve 70W optical power.

Figure 3.3: Close-up of the linear guide rail and reinforced shaft, highlighting the sturdy and stable mechanical design for precise movement.

4. Setup

The IKIER K1 Pro Max features a modular design for quick and easy assembly, typically within 15 minutes.

4.1 Spakkjar u Armar

- Neħħi bir-reqqa l-komponenti kollha mill-imballaġġ.

- Follow the included quick assembly guide to connect the main frame components. Ensure all screws are tightened securely.

- Installa l-modulu tal-lejżer fuq il-gantry.

- Connect the air assist unit to the designated port on the machine.

4.2 Konnessjoni tal-Enerġija

Connect the provided DC power adapter to the machine's power input port and then to a suitable power outlet.

4.3 Installazzjoni tas-Softwer

The IKIER K1 Pro Max is compatible with popular laser control software such as LightBurn and LaserGRBL. Download the latest version of your preferred software from the official websiti.

- LightBurn: Recommended for advanced users, offering comprehensive control and design features.

- LaserGRBL: A free and open-source option, suitable for basic engraving tasks.

4.4 Metodi ta' Konnessjoni

The machine supports multiple connection interfaces:

- USB: Connect directly to your computer via a USB cable.

- WLAN (Wi-Fi): Connect wirelessly to your network for convenient control.

- Karta TF: Load design files directly onto a TF card for offline operation using the 4.3-inch touch screen.

5. Istruzzjonijiet Operattivi

5.1 Tixgħel/Jitfi

To power on the machine, flip the physical switch located on the control panel. To power off, flip the switch back to the OFF position.

5.2 Tħejjija tal-Materjal

Place your chosen material flat on the engraving bed. Ensure it is securely positioned to prevent movement during operation. The machine can engrave and cut a variety of materials, including:

- Materjali tal-inċiżjoni: Wood, bamboo, cardboard, plastic, leather, PCB plate, oxidized aluminum, non-dazzling electroplating and lacquered metal, 304 mirror stainless steel, glass, ceramic, cotton, slate.

- Materjali tal-Qtugħ: Cardboard, non-woven fabric, wood, acrylic, thin plastic plates, sponges.

Figure 5.1: Demonstrations of the cutting capability on Paulownia wood and black acrylic, showcasing the machine's ability to cut thick materials in a single pass.

5.3 L-Iffukar tal-Laser

The IKIER K1 Pro Max features an intelligent Z-axis for automatic focusing:

- Fokus Awtomatiku: Press the auto-focus button on the control panel or via the software. The laser will automatically adjust its height to achieve optimal focus on the material surface. This process takes approximately 8 seconds.

- Focus Manwal: For fine adjustments or specific applications, the Z-axis can also be adjusted manually.

Figure 5.2: Illustration of the extended laser beam waist, which contributes to the machine's enhanced cutting capabilities and deeper penetration.

5.4 Loading Designs and Framing

Ipprepara d-disinn tiegħek file using compatible software (LightBurn, LaserGRBL). The machine supports various file types including SVG, DXF, JPG, JPEG, PNG, BMP, TIF, CR2, etc.

- Kontroll tas-Softwer: Load your design into the software and use the framing function to preview the engraving area on your material using the laser's cross positioning system.

- Operazzjoni Offline: Save your design to a TF card and insert it into the machine. Use the 4.3-inch LCD touch screen to select and initiate the job.

Figure 5.3: The cross positioning system in action, demonstrating its utility for precise alignment and visual framing of the engraving area.

5.5 Adjusting Air Assist

The intelligent air assist system can be adjusted from 0-60 l/min. Adjust the airflow based on the material and desired cutting/engraving effect. Higher airflow generally helps with cleaner cuts and reduces charring.

5.6 Bidu tal-Operazzjoni

Once the material is placed, laser is focused, and design is loaded and framed, you can start the engraving or cutting process from your software or the touch screen. Monitor the operation closely, especially for new materials or settings.

6. Manutenzjoni

Regular maintenance ensures the longevity and optimal performance of your IKIER K1 Pro Max.

- Tindif tal-Lenti tal-Laser: Periodically inspect and clean the laser lens using a lint-free cloth and lens cleaning solution. A dirty lens can significantly reduce laser power and engraving quality.

- Cleaning Air Assist Channels: The intelligent air assist has a double-layer design to prevent blockages, but occasional inspection and cleaning of the air channels are recommended to ensure continuous flow.

- Tindif tal-Korp tal-Magni: Wipe down the machine's exterior and engraving bed regularly to remove dust and debris.

- Linear Rail Inspection: Check the linear guide rails for any debris or wear. Keep them clean and lightly lubricated if necessary, following manufacturer recommendations.

- Aġġornamenti tal-Firmware: Iċċekkja l-IKIER uffiċjali webżur is-sit għal kwalunkwe aġġornament tal-firmware disponibbli biex tiżgura li l-magna tiegħek għandha l-aħħar karatteristiċi u titjib fil-prestazzjoni.

7 Issolvi l-problemi

Din it-taqsima tindirizza kwistjonijiet komuni li tista' tiltaqa' magħhom. Għal problemi aktar kumplessi, jekk jogħġbok ikkuntattja l-appoġġ għall-klijenti.

- Il-magna ma tixgħelx:

- Iċċekkja jekk il-kejbil tal-enerġija huwiex imqabbad sew kemm mal-magna kif ukoll mas-sokit tal-enerġija.

- Ensure the physical power switch is in the 'ON' position. - Il-Laser Mhux Jaħdem jew Ħruġ Dgħajjef:

- Verify that the laser module is properly connected.

- Clean the laser lens as described in the Maintenance section.

- Ensure the laser is correctly focused on the material surface.

- Check laser power settings in your control software. - Kwalità Fqira tal-Inċiżjoni/Qtugħ:

- Adjust laser power and speed settings for the specific material.

- Ensure the material is flat and securely placed.

- Verify laser focus.

- Naddaf il-lenti tal-lejżer.

- Check if the air assist is functioning correctly and adjusted appropriately. - Machine Not Connecting to Computer/Software:

- Check USB cable connection or Wi-Fi settings.

- Ensure correct drivers are installed for your operating system.

- Restart both the machine and your computer. - Machine Stops Unexpectedly:

- Check for safety feature activation (flame detection, tilt detection). Address the cause (e.g., extinguish flame, ensure stable surface).

- Ensure proper ventilation to prevent overheating. - Air Assist Not Functioning:

- Check the connection of the air assist unit.

- Ensure the air assist current is set correctly (0-60 l/min).

- Inspect air assist channels for blockages.

8. Speċifikazzjonijiet

| Karatteristika | Speċifikazzjoni |

|---|---|

| Brand | IKIER |

| Mudell | K1 Pro Max 70W |

| Daqs tal-inċiżjoni | 410mm x 410mm |

| Qawwa tal-Magni | 360W |

| Qawwa tal-Laser | 70-77W (Output), 35-39W (Diode Power) |

| Maximum Movement Rate | 900mm/s |

| Daqs tal-Post | 0.15 mm x 0.2 mm (70W), 0.10 mm x 0.15 mm (35W) |

| Preċiżjoni tal-inċiżjoni | 0mm (as per manufacturer specification) |

| Laser Wave | 455 ± 5 sq m |

| Metodu ta 'ffokar | Automatic or Manual Focus with Infrared Positioning |

| Kompatibilità tas-Sistema Operattiva | Windows, MacOS, Android, iOS |

| Kontroll Software | LightBurn, LaserGRBL |

| Appoġġjati File Tipi | SVG, DXF, JPG, JPEG, PNG, BMP, TIF, CR2, etc. |

| Interface tal-Konnessjoni | USB, WLAN, TF card |

| Motherboard | 32-bit control card with Wi-Fi |

| Handlebar Terminal | Skrin tat-Touch LCD ta' 4.3" |

| Swiċċijiet tat-Tmiem | 5 (X-axis 2, Y-axis 2, Z-axis 1) |

| Air Support Current | 0-60 l/min (infinitely adjustable) |

| Komponenti Inklużi | 1 x IKIER K1 Pro Max 70W Machine |

Figure 8.1: Comparative specifications between the IKIER K1 Pro Max 70W semiconductor laser and a typical 180W CO2 laser, highlighting differences in laser type, weight, cutting capacity, and dimensions.

9. Garanzija u Appoġġ

For warranty information, technical support, or service inquiries, please refer to the official IKIER webis-sit jew ikkuntattja lin-negozjant awtorizzat tiegħek. Żomm l-irċevuta tax-xiri tiegħek bħala prova tax-xiri għal talbiet ta' garanzija.

For the latest drivers, software updates, and additional resources, please visit the official IKIER support page.