1. Prodott Aktarview

The Forney 42463 is a low-hydrogen welding electrode designed for welding mild steel. This electrode is specifically formulated to minimize hydrogen content in the weld metal, which helps prevent cracking in critical applications. It is suitable for a variety of welding tasks where high-quality, crack-resistant welds are required.

Key characteristics include:

- Suitable for cold rolled steels that may exhibit excessive porosity with conventional rods.

- Ideal for field erections, steel structures, frames, trailer hitches, and chassis.

- Manufactured to ensure consistent performance.

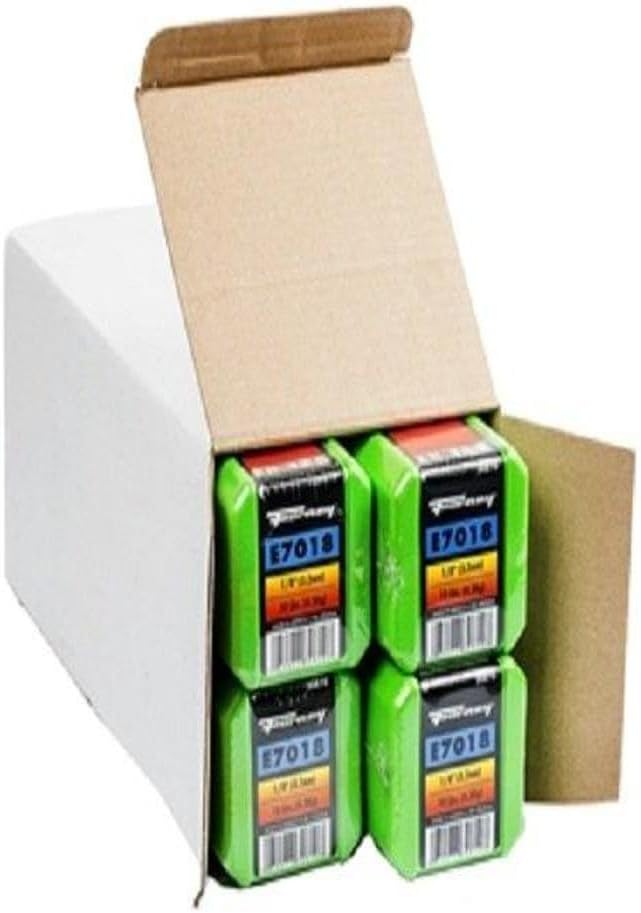

Image 1: A box containing multiple packs of Forney 42463 Low-Hydrogen Welding Electrodes. Each pack is green and labeled "E7018", indicating the electrode type.

2. Setup u Preparazzjoni

Proper setup and preparation are crucial for achieving optimal welding results with low-hydrogen electrodes.

2.1 Electrode Storage and Handling

Low-hydrogen electrodes are sensitive to moisture absorption, which can lead to hydrogen-induced cracking in welds. Store electrodes in a dry, heated environment, such as a heated oven or sealed container, to maintain their low-hydrogen properties. If electrodes have been exposed to moisture, re-baking according to manufacturer specifications may be necessary before use.

2.2 Tħejjija tal-Biċċa tax-Xogħol

Ensure the workpiece is clean and free from rust, oil, grease, paint, and other contaminants. Proper cleaning prevents weld defects and ensures good arc stability and penetration.

2.3 Welding Machine Settings

Refer to your welding machine's manual for specific settings. For E7018 electrodes, typical settings include:

- Polarità: Direct Current Electrode Positive (DCEP), also known as Reverse Polarity.

- Ampetà: Adjust based on electrode diameter and joint configuration. Consult a welding chart for recommended ranges.

- Tul tal-Ark: Maintain a short arc length for optimal shielding and penetration.

3. Istruzzjonijiet Operattivi

Follow these guidelines for effective and safe operation of the Forney 42463 electrode.

3.1 Welding Technique

- Saħħan minn qabel: For thicker sections or high-carbon steels, preheating the base metal may be necessary to prevent cracking.

- Veloċità tal-Ivvjaġġar: Maintain a consistent travel speed to ensure proper bead shape and penetration. Too fast can lead to shallow penetration; too slow can cause excessive heat input and distortion.

- Angolu tal-Elettrodu: Hold the electrode at a slight angle (10-20 degrees) in the direction of travel.

- Weaving: A slight weaving motion can be used to control bead width and penetration, especially on wider joints.

- Tneħħija tal-gagazza: The slag produced by E7018 electrodes is typically easy to remove. Ensure all slag is removed between passes to prevent inclusions.

3.2 Prekawzjonijiet tas-Sigurtà

Always prioritize safety when welding. Wear appropriate Personal Protective Equipment (PPE), including:

- Welding helmet with appropriate shade lens.

- Flame-resistant clothing.

- Welding gloves.

- Nuċċalijiet tas-sigurtà.

- Respirator (if welding in confined spaces or with inadequate ventilation).

Ensure adequate ventilation to disperse welding fumes. Be aware of fire hazards and have fire extinguishing equipment readily available.

4. Manutenzjoni

The Forney 42463 welding electrodes themselves do not require maintenance. However, proper storage is critical to maintain their performance.

4.1 Electrode Storage

Store unused electrodes in a dry, temperature-controlled environment. For opened packages, consider using a portable electrode oven or a sealed, moisture-proof container to prevent moisture absorption. High humidity can degrade the electrode's low-hydrogen properties, leading to potential weld defects.

5. Issolvi l-problemi ta' Kwistjonijiet Komuni

While using low-hydrogen electrodes, you might encounter some common welding issues. Here are potential causes and solutions:

| Ħruġ | Kawża Possibbli | Soluzzjoni |

|---|---|---|

| Porożità fil-Weld | Moisture in electrode coating, insufficient shielding, contaminated base metal. | Re-bake electrodes, ensure proper arc length, clean base metal thoroughly. |

| Cracking (Hydrogen-induced) | High hydrogen content, insufficient preheat/post-heat, high restraint. | Ensure electrodes are dry, apply proper preheat/post-heat, reduce joint restraint. |

| Poor Arc Stability | Skorretta amperage, poor ground connection, contaminated electrode. | Aġġusta amperage, check ground clamp, use clean electrodes. |

| Spatter Eċċessiv | Amperage too high, arc length too long. | Naqqas amperage, shorten arc length. |

6. Speċifikazzjonijiet

Detailed specifications for the Forney 42463 Low-Hydrogen Welding Electrode:

- Isem tal-Mudell: Forney 42463 Low-Hydrogen Welding Electrode, Mild Steel, 15" L

- Numru tal-Parti: 42463

- Ditta: Forney

- Materjal: Mild Steel (electrode core)

- Tul tal-oġġett: 15 pulzieri

- Piż tal-oġġett: Approximately 10 Pounds (for the package)

- Dimensjonijiet tal-Pakkett (L x W x H): 15.98 x 7.52 x 7.24 pulzieri

- Piż tal-Pakkett: 4990 Gramm

- Manifattur: Forney

- ASIN: B075QCDQRH

7. Informazzjoni dwar Garanzija

The Forney 42463 Low-Hydrogen Welding Electrode comes with a standard manufacturer's warranty. For specific details regarding warranty coverage, duration, and claims procedures, please refer to the official Forney warranty documentation provided with your purchase or visit the official Forney website. The general warranty description is stated as "Warranty".

8. Appoġġ għall-Klijent

For further assistance, technical questions, or support regarding the Forney 42463 Low-Hydrogen Welding Electrode, please contact Forney customer service. You can typically find contact information on the product packaging or by visiting the official Forney websit: