1. Introduzzjoni

The Milescraft 1319 JointMate is a versatile handheld dowel jig designed for creating strong and precise corner, edge, and surface joints in woodworking projects. Its self-centering mechanism and adjustable fence ensure accurate dowel alignment, making it an essential tool for both hobbyists and professionals.

This manual provides detailed instructions for the safe and effective use, setup, operation, and maintenance of your Milescraft 1319 Joint Mate.

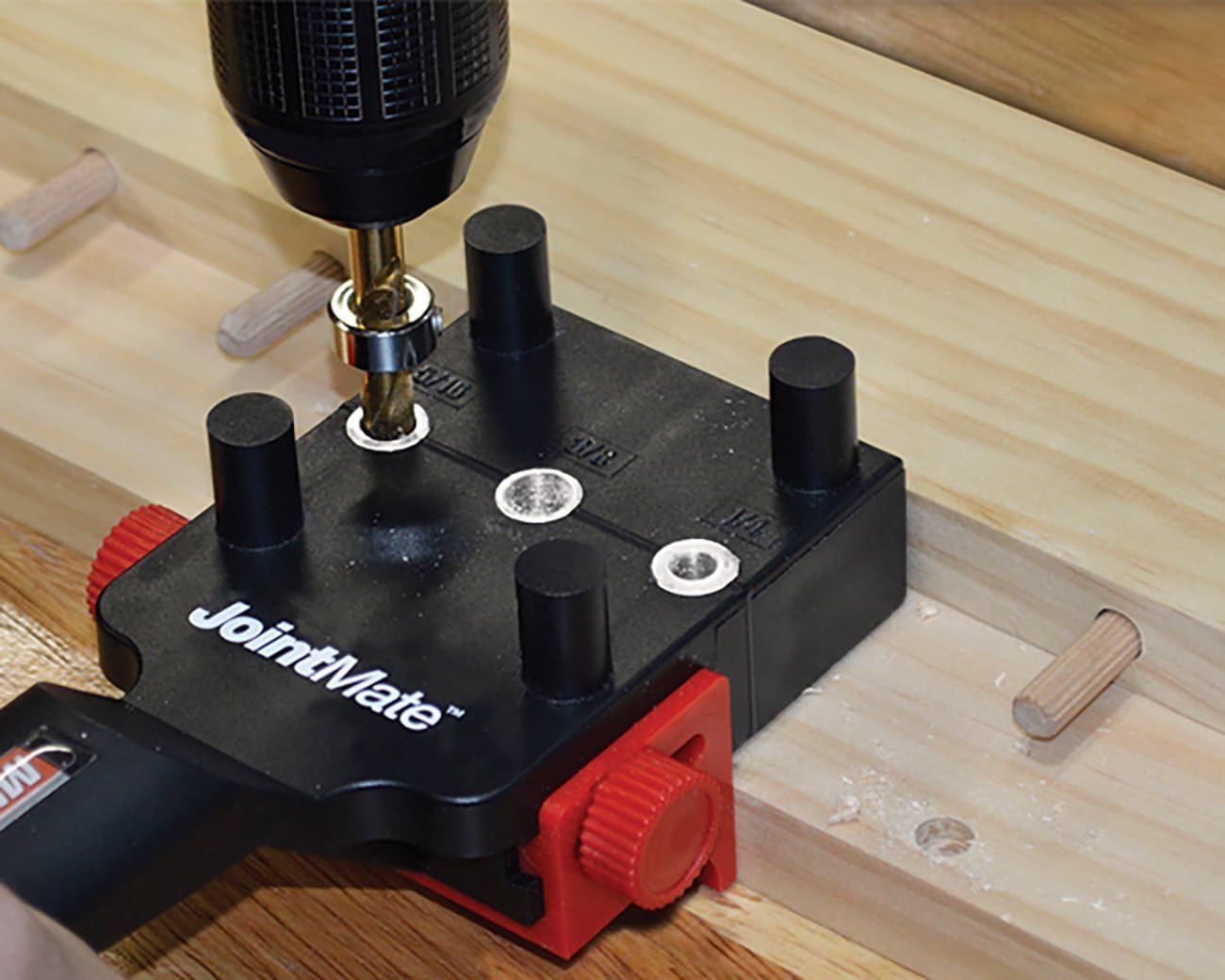

Figure 1.1: The Milescraft 1319 Joint Mate handheld dowel jig, featuring its black body, red adjustable fence, and metal bushing inserts.

2. Informazzjoni dwar is-Sigurtà

Always observe basic safety precautions when using power tools and accessories. Failure to do so may result in serious injury or property damage.

Linji Gwida Ġenerali dwar is-Sigurtà:

- Aqra u ifhem l-istruzzjonijiet kollha qabel ma tħaddem l-għodda.

- Ilbes tagħmir protettiv personali (PPE) xieraq, inklużi nuċċalijiet tas-sigurtà, protezzjoni għas-smigħ, u ingwanti.

- Ensure your work area is clean, well-lit, and free of clutter.

- Żomm lit-tfal u lil dawk li jkunu fil-qrib 'il bogħod waqt li tħaddem l-għodda.

- Always secure your workpiece firmly before drilling.

- Use sharp drill bits appropriate for the material being drilled.

- Do not force the tool; let the drill bit do the work.

- Disconnect power tools from the power source before making any adjustments or changing accessories.

- Store the Joint Mate and accessories in a dry, secure place when not in use.

TWISSIJA: Dan il-prodott jista' jesponik għal kimiċi inkluż iċ-ċomb, li huwa magħruf mill-Istat ta' Kalifornja li jikkawża kanċer u difetti fit-twelid jew ħsara riproduttiva oħra. Għal aktar informazzjoni mur fuq www.P65Warnings.ca.gov.

3. Kontenut tal-Pakkett

Ivverifika li l-oġġetti kollha huma preżenti u bla ħsara malli tiftaħ il-pakkett:

- Milescraft 1319 Joint Mate Dowel Jig

- Adjustable Guide Fence

- Guide Fence Knobs (2)

- Manwal ta' Istruzzjoni

Note: Drill bits, dowel pins, and stop collars are sold separately and are not included with the Joint Mate.

4. Karatteristiċi ewlenin

The Milescraft 1319 Joint Mate is engineered with features to enhance precision and ease of use:

- Self-Centering Jig: Automatically centers the jig on the edge of the workpiece for accurate drilling.

- Adjustable Fence: Allows for precise dowel alignment and accommodates various board thicknesses from 1/2" to 1-1/2" (12.7mm to 38.1mm).

- Metal Bushings: Durable metal drill guide bushings (1/4", 5/16", 3/8") ensure accurate and repeatable hole drilling, preventing wear on the jig body.

- Tipi ta' Ġonta Versatili: Capable of creating corner, edge, and surface joints.

- Setup Minimu: Designed for quick and easy preparation without complex adjustments.

5. Setup

Before beginning any drilling operation, ensure the Joint Mate is properly configured for your workpiece and desired joint type.

5.1 Attaching the Adjustable Fence

- Locate the adjustable guide fence and the two guide fence knobs.

- Align the holes in the fence with the threaded inserts on the side of the Joint Mate body.

- Insert the guide fence knobs through the fence and thread them into the inserts.

- Tighten the knobs finger-tight to secure the fence. Do not overtighten.

5.2 Adjusting for Material Thickness

The adjustable fence allows the Joint Mate to accommodate lumber thicknesses from 1/2" to 1-1/2".

- Loosen the two guide fence knobs.

- Slide the fence along the body of the Joint Mate until it is positioned correctly for your material thickness. The jig's self-centering pins will help align it.

- Place the Joint Mate onto the edge of your workpiece to verify the centering. The jig should sit snugly and centered.

- Once centered, tighten the guide fence knobs firmly to lock the fence in place.

5.3 Selecting Drill Bit Size

The Joint Mate features three common dowel sizes: 1/4", 5/16", and 3/8".

- Choose a drill bit that matches the size of the dowel pins you intend to use.

- Insert the drill bit into the appropriate metal bushing on the Joint Mate.

- Attach a depth stop collar to your drill bit to control drilling depth, ensuring consistent dowel insertion.

6. Operazzjoni

The Milescraft 1319 Joint Mate simplifies the process of creating strong dowel joints. Follow these steps for various joint configurations.

6.1 Tħejjija tal-Biċċa tax-Xogħol

- Ensure all workpieces are cut square and to the correct dimensions. Inaccurate cuts will lead to misaligned joints.

- Mark the exact locations where you intend to drill your dowel holes on both pieces of lumber. Precision in marking is crucial for joint alignment.

- Secure your workpiece firmly to a workbench using clamps. This prevents movement during drilling and ensures accuracy.

6.2 Creating Edge Joints

Edge joints are used to join two boards along their long edges, typically for wider panels.

- Adjust the fence to the thickness of your material as described in Section 5.2.

- Place the Joint Mate onto the edge of the first workpiece, aligning the desired drill bushing with your marked hole location. The self-centering pins will help maintain alignment.

- Hold the Joint Mate firmly against the workpiece.

- Using your drill with the appropriate drill bit and depth stop, drill the hole through the metal bushing.

- Repeat for all desired dowel locations on the first workpiece.

- For the second workpiece, align the Joint Mate in the same manner, ensuring the corresponding holes will match up. Drill the holes.

Figure 6.1: Drilling a dowel hole using the Milescraft Joint Mate on a wooden board. The jig is held firmly in place while the drill bit enters the metal bushing.

6.3 Creating Corner Joints

Corner joints are used to join two pieces of wood at a 90-degree angle.

- For the first piece (e.g., the face of a board), place the Joint Mate flat on the surface, aligning the desired bushing with your marked hole. Drill the hole.

- For the second piece (e.g., the end of a board), adjust the fence and place the Joint Mate on the end grain, aligning the bushing with the corresponding marked hole. Drill the hole.

- Ensure that the holes on both pieces will align perfectly when the joint is assembled.

Figure 6.2: The Joint Mate positioned on the edge of a wooden board for drilling, demonstrating its self-centering capability.

6.4 Creating Surface Joints

Surface joints involve drilling into the face of a board to attach another piece, often used for shelves or internal supports.

- Mark the precise location for the dowel holes on the surface of the workpiece.

- Position the Joint Mate over the marked location. The self-centering pins are primarily for edges, so careful manual alignment is necessary for surface drilling.

- Hold the jig firmly in place or use clamps biex jipprevjenu moviment.

- Drill the hole to the desired depth.

- Repeat for all necessary holes.

6.5 Assemblea

- Apply wood glue to the dowel holes and along the mating surfaces of the workpieces.

- Insert dowel pins into the drilled holes on one workpiece.

- Align the second workpiece and press the two pieces together, ensuring the dowel pins enter the corresponding holes.

- Clamp the joint firmly until the glue dries, wiping away any excess glue.

7. Manutenzjoni

Proper maintenance will extend the life and accuracy of your Milescraft 1319 Joint Mate.

- Tindif: After each use, wipe down the Joint Mate with a dry cloth to remove sawdust and debris. Do not use harsh chemicals or solvents.

- Lubrikazzjoni: The metal bushings do not require lubrication.

- Ħażna: Store the Joint Mate in a clean, dry environment, away from direct sunlight and extreme temperatures. Keep it in its original packaging or a dedicated storage container to protect it from damage.

- Spezzjoni: Periodically inspect the jig for any signs of wear or damage, especially to the metal bushings and the adjustable fence mechanism. Replace any worn or damaged parts immediately.

8 Issolvi l-problemi

If you encounter issues while using your Milescraft 1319 Joint Mate, refer to the following common problems and solutions:

| Problema | Kawża Possibbli | Soluzzjoni |

|---|---|---|

| Dowel holes are misaligned. |

|

|

| Drill bit wanders or creates oversized holes. |

|

|

| Jig slips during drilling. |

|

|

9. Speċifikazzjonijiet

| Attribut | Dettall |

|---|---|

| Numru tal-Mudell | 1319 |

| Manifattur | Milescraft, Inc. |

| Materjal | ABS Plastic (Body), Metal (Bushings) |

| Piż tal-oġġett | 9.6 uqija (madwar 272 gramma) |

| Dimensjonijiet tal-Prodott | 10 x 4 x 2 pulzieri (madwar 25.4 x 10.16 x 5.08 ċm) |

| Compatible Lumber Thickness | 1/2" to 1-1/2" (12.7mm to 38.1mm) |

| Bushing Sizes | 1/4", 5/16", 3/8" |

| Sors tal-Enerġija | Hand Powered (requires external drill) |

10. Garanzija u Appoġġ

Milescraft stands behind the quality of its products. For specific warranty information, product registration, or technical support, please visit the official Milescraft websit jew ikkuntattja lid-dipartiment tas-servizz tal-konsumatur tagħhom.

Milescraft Official Websit: www.milescraft.com

Għal aktar assistenza, tista' tirreferi wkoll għall- Manwal għall-Utent (PDF) disponibbli online.