1. Introduzzjoni

This instruction manual provides essential information for the safe and efficient operation, setup, and maintenance of your Mafell ZSX Twin Ec Carpentry Chainsaw. Please read this manual thoroughly before using the tool to ensure proper handling and to prevent injury or damage.

Prodott Overview

The Mafell ZSX Twin Ec is a powerful carpentry chainsaw designed for processing large timber components. It features two CUprex motors, allowing for high performance even when power is distributed across two electrical circuits. This design ensures the tool receives the necessary power without overloading the network. It is ideal for longitudinal cuts up to 400 mm deep and facilitates precise angle cuts and overlaps in timber construction.

Figure 1: Mafell ZSX Twin Ec Carpentry Chainsaw, front view. This image shows the overall design of the chainsaw, highlighting its robust construction and dual motor housing.

2. Istruzzjonijiet tas-Sigurtà

TWISSIJA: Aqra t-twissijiet, l-istruzzjonijiet, l-illustrazzjonijiet u l-ispeċifikazzjonijiet kollha dwar is-sigurtà pprovduti ma’ din l-għodda tal-enerġija. In-nuqqas li ssegwi l-istruzzjonijiet kollha elenkati hawn taħt jista’ jirriżulta f’xokk elettriku, nar, u/jew korriment serju.

- Tagħmir Protettiv Personali (PPE): Always wear safety glasses, hearing protection, gloves, and appropriate footwear. A hard hat and leg protection are also recommended.

- Sigurtà taż-Żona tax-Xogħol: Żomm iż-żona tax-xogħol nadifa u mdawwla sew. Żoni imbarazzati jew mudlama jistiednu inċidenti. Tħaddimx għodod tal-enerġija f'atmosferi splussivi, bħal fil-preżenza ta' likwidi, gassijiet jew trab fjammabbli.

- Sigurtà Elettrika: Il-plakek tal-għodda tal-enerġija għandhom jaqblu mas-sokit. Qatt ma timmodifika l-plakka bl-ebda mod. Evita kuntatt tal-ġisem ma' uċuħ ertjati jew imqabbdin mal-art.

- Operazzjoni tal-Għodda: Do not overreach. Keep proper footing and balance at all times. Use the correct tool for your application. Do not force the tool.

- Prevenzjoni ta' Kickback: Be aware of kickback. Maintain a firm grip with both hands on the chainsaw. Ensure the chain is sharp and properly tensioned.

- Manutenzjoni: Skonnettja l-plagg mis-sors tal-enerġija qabel ma tagħmel xi aġġustamenti, tbiddel l-aċċessorji, jew taħżen għodda tal-enerġija.

- Tfal u Persuni li Qegħdin fil-Viċin: Żomm lit-tfal u lil dawk li jkunu fil-qrib 'il bogħod waqt li tħaddem għodda tal-enerġija.

3. Setup u Assemblea

3.1 Spakkjar u Spezzjoni

Carefully unpack all components. Inspect the tool for any damage that may have occurred during transit. If any damage is found, do not operate the tool and contact your dealer immediately.

3.2 Installing the Saw Chain

- Ensure the tool is disconnected from the power supply.

- Refer to the chain installation diagram (if available in the full manual) for proper orientation.

- Mount the chain onto the guide bar, ensuring the cutting teeth are facing the correct direction.

- Adjust chain tension according to the manufacturer's guidelines. The chain should be snug but still able to be pulled around the guide bar by hand.

3.3 Attaching the Parallel Stop and Guide Rail

For precise longitudinal cuts, attach the parallel stop and guide rail as follows:

- Slide the parallel stop into the designated slots on the base plate.

- Secure the parallel stop at the desired measurement for your cut.

- For extended precision, align the chainsaw with the Mafell guide rail (Part No. 205934) and secure it.

Figure 2: Base plate with angle adjustment. This image illustrates the markings and mechanism for setting the cutting angle, crucial for precise carpentry work.

Figure 3: Angle adjustment mechanism. A closer look at the swivel mechanism, showing the degree scale from -15° to +60° for versatile cutting angles.

4. Istruzzjonijiet Operattivi

4.1 Konnessjoni tal-Enerġija

The ZSX Twin Ec operates on two 230 V phases. Connect the two power cables to separate 230 V/50 Hz circuits to ensure optimal power distribution and prevent overload.

4.2 Aġġustament tal-Fond u l-Angolu tat-Tqattigħ

- Qtugħ tal-fond: Adjust the guide bar to achieve the desired cutting depth, up to a maximum of 400 mm.

- Aġġustament tal-Angolu: The saw can be pivoted from -15° to +60°. Use the angle scale on the base plate to set the precise angle for your cuts.

4.3 Nagħmlu Qatgħa

- Kun żgur li l-biċċa tax-xogħol tkun clamped.

- Position the chainsaw on the workpiece, ensuring the guide rail (if used) is properly aligned.

- Start the motor and allow it to reach full speed before engaging the workpiece.

- Guide the chainsaw smoothly and steadily through the material. Do not force the tool.

- After completing the cut, release the trigger and allow the chain to stop before lifting the tool from the workpiece.

Figure 4: Chainsaw in operation. This image shows the chainsaw actively cutting timber, with visible sawdust, indicating its powerful performance and potential for dust extraction.

5. Manutenzjoni

Regular maintenance ensures the longevity and safe operation of your Mafell ZSX Twin Ec.

5.1 Tindif

- After each use, disconnect the tool from the power supply.

- Clean the tool thoroughly, removing sawdust and debris from the motor housing, guide bar, and chain. Use a brush or compressed air.

- Ensure the dust extraction port is clear.

Figure 5: Dust extraction port. This close-up highlights the design of the dust extraction system, which helps maintain a cleaner work environment and prolong tool life.

5.2 Chain Lubrication and Sharpening

- Regularly check the chain for sharpness. A dull chain can cause kickback and reduce cutting efficiency. Sharpen or replace the chain as needed.

- Ensure the automatic chain lubrication system (if present) is functioning correctly and the oil reservoir is filled with appropriate chain oil.

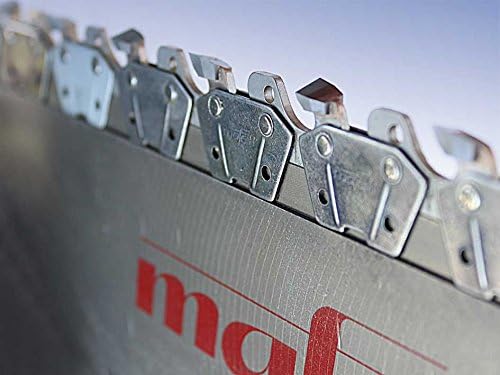

Figure 6: Chainsaw chain teeth. A detailed view of the cutting teeth, emphasizing the importance of sharpness for effective and safe operation.

5.3 Spezzjoni Ġenerali

- Iċċekkja l-viti u l-qafliet kollha għal issikkar.

- Spezzjona l-kejbils tad-dawl għal ħsara.

- Kun żgur li l-protezzjonijiet tas-sigurtà kollha huma f'posthom u jaħdmu sew.

6 Issolvi l-problemi

This section addresses common issues you might encounter with your Mafell ZSX Twin Ec. For problems not listed here, contact qualified service personnel.

| Problema | Kawża Possibbli | Soluzzjoni |

|---|---|---|

| Għodda ma tibda | No power supply; faulty cable; motor overload protection activated. | Check power connection and circuit breakers. Inspect cables for damage. Allow motor to cool down. |

| Prestazzjoni mnaqqsa tat-tqattigħ | Katina matt; tensjoni mhux korretta tal-katina; lubrikazzjoni insuffiċjenti. | Sharpen or replace chain. Adjust chain tension. Check chain oil reservoir and lubrication system. |

| Vibrazzjoni eċċessiva | Loose components; damaged chain or guide bar. | Check all fasteners. Inspect chain and guide bar for damage and replace if necessary. |

7. Speċifikazzjonijiet Tekniċi

| Mudell | ZSX Twin Ec |

| Brand | Mafell |

| Referenza tal-Manifattur | 961601 |

| Sors tal-Enerġija | Enerġija tal-Mejns |

| Voltage | 230 V / 50 Hz (per phase, dual connection) |

| Qawwa Nominali | 2 x 3000 W (6000 W total) |

| Nominal No-Load Speed | 3600 rpm |

| Fond tal-Qtugħ | 400 mm |

| Fond tal-Qtugħ f'45 ° | 282 mm |

| Fond tal-Qtugħ f'60 ° | 199 mm |

| Medda li ddur | -15° sa +60° |

| Wisa' tal-Qtugħ | 6.8 mm |

| Piż tal-Għodda | Appross. 24.2 kg |

| Dimensjonijiet tal-Prodott (L x W x H) | 0.03 x 0.03 x 0.03 ċm |

| Aċċessorji Inklużi |

|

Note on Weight: The product description states 24.2 kg, while feature bullets mention 20 kg, and specifications list 56 kg. The 24.2 kg is used here as the most likely operational weight. The 56 kg might refer to the shipping weight including packaging and accessories.

Note on Dimensions: The provided dimensions (0.03 x 0.03 x 0.03 cm) appear to be incorrect. Please refer to the official product packaging or manufacturer's website for accurate physical dimensions.

8. Garanzija u Appoġġ

For warranty information, please refer to the warranty card included with your product or contact your authorized Mafell dealer. Keep your proof of purchase for any warranty claims.

For technical support, spare parts, or service, please contact Mafell customer service or your local authorized service center. Contact details can typically be found on the manufacturer's websit jew fl-ippakkjar tal-prodott.