Informazzjoni Importanti dwar is-Sigurtà

TWISSIJA: All controls should be installed by a licensed professional. Failure to read and follow all instructions carefully before installing or operating this control could cause personal injury and/or property damage.

This manual provides detailed instructions for the safe and proper installation, operation, and maintenance of the ProTech 607011 Spark Pilot Furnace Gas Valve. Please read this manual thoroughly before proceeding with any procedures.

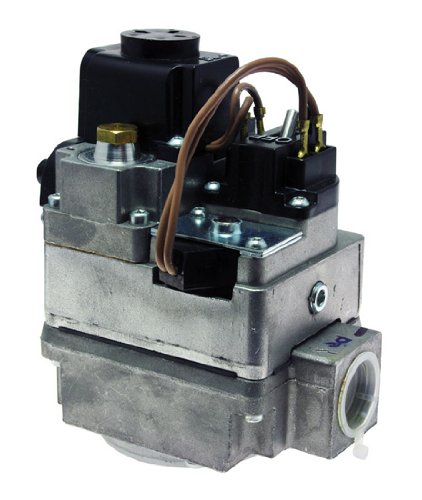

Deskrizzjoni tal-Immaġni: A dettaljata view of the ProTech 607011 Spark Pilot Furnace Gas Valve. The valve features a robust metal body with various connections and wiring for spark pilot ignition systems. A black electrical component is visible on the top, with brown wires connected to brass terminals. Threaded input and output ports are located on the sides of the valve body, designed for gas line connections.

1. Setup u Installazzjoni

The ProTech 607011 Spark Pilot Furnace Gas Valve is designed for use in furnace systems requiring a spark pilot ignition. Proper installation is critical for safe and efficient operation.

1.1 Lista ta 'Kontroll ta' Qabel l-Installazzjoni

- Ensure the main gas supply to the appliance is turned off.

- Verify that the new gas valve matches the specifications of the original part.

- Iġbor l-għodda u t-tagħmir tas-sigurtà kollha meħtieġa.

- Confirm that the installation will be performed by a licensed professional.

1.2 Passi ta' Installazzjoni

- Skonnettja l-enerġija elettrika mal-forn.

- Turn off the main gas supply valve to the furnace.

- Carefully remove the old gas valve, noting all connections (gas lines, wiring).

- Apply appropriate pipe thread sealant (e.g., Rectorseal Pipe Thread Sealant #5) to the threads of the gas lines before connecting them to the new valve.

- Connect the input and output gas lines to the new ProTech 607011 valve. Ensure all connections are tight and leak-free.

- Connect the wiring harness (e.g., White-Rodgers F115-0059 / 45-25204-01) to the appropriate terminals on the gas valve. Refer to the furnace manufacturer's wiring diagram for correct connections.

- Mount the gas valve securely within the furnace.

- Slowly turn on the main gas supply and check for leaks using a suitable leak detection solution.

- Irrestawra l-enerġija elettrika għall-forn.

- Perform initial startup and operational checks as per the furnace manufacturer's instructions.

1.3 Aċċessorji Rakkomandati

- Rectorseal Pipe Thread Sealant #5 - 1/2 Pint

- Bramec White Teflon Tape 3/4" X 520'

- Gas Pressure Test Kit Manometer

- J/B Black Gas Pipe Fittings

2. Istruzzjonijiet Operattivi

The ProTech 607011 gas valve operates in conjunction with the furnace's control system to regulate gas flow to the pilot and main burner.

2.1 Operazzjoni Normali

- Upon a call for heat, the furnace control board sends a signal to the gas valve.

- The gas valve opens to allow gas to flow to the pilot burner.

- The spark igniter creates a spark to ignite the pilot flame.

- Once the pilot flame is established and sensed by the flame sensor, the gas valve opens further to allow gas to flow to the main burner.

- The main burner ignites, and the furnace begins its heating cycle.

- When the thermostat's call for heat is satisfied, the gas valve closes, shutting off gas to the main and pilot burners.

2.2 Gas Type Conversion

This valve is designed for both Natural Gas and LP (Liquid Propane) applications. An LP conversion kit is included. Conversion must be performed by a licensed professional according to the instructions provided with the conversion kit and the furnace manufacturer's guidelines.

- LP Spring Kit: 60-21193-01

- Natural Gas Spring Kit: 60-21193-02

3. Manutenzjoni

Regular maintenance of your furnace system, including the gas valve, is essential for safe and efficient operation. All maintenance procedures should be performed by a licensed professional.

3.1 Spezzjoni Annwali

- Inspect all gas connections for leaks.

- Check wiring connections for corrosion or damage.

- Verify proper pilot ignition and main burner flame characteristics.

- Ensure the gas valve opens and closes smoothly without hesitation.

- Clean any dust or debris from the exterior of the valve.

3.2 Tindif

The gas valve itself typically does not require internal cleaning. External cleaning should be limited to wiping with a dry cloth to remove dust. Do not use harsh chemicals or solvents.

4 Issolvi l-problemi

If your furnace is not operating correctly, consult a licensed HVAC professional. Do not attempt to repair the gas valve yourself. The following are common issues that may indicate a problem with the gas valve or related components:

- Ebda Tqabbid: If the pilot or main burner does not ignite, check for gas supply, proper electrical connections, and a functioning igniter/flame sensor.

- Operazzjoni intermittenti: The furnace cycles on and off unexpectedly. This could be due to a faulty flame sensor, low gas pressure, or an issue with the gas valve's internal components.

- Gas Leak Smell: If you detect the smell of gas, immediately turn off the gas supply to the furnace and contact a professional. Do not attempt to operate the furnace.

- Pilot Light Issues: Pilot light does not stay lit, or is difficult to light. This could indicate a problem with the pilot assembly, thermocouple/thermopile, or the pilot section of the gas valve.

For all troubleshooting and repairs, it is strongly recommended to contact a qualified service technician.

5. Speċifikazzjonijiet

| Karatteristika | Dettall |

|---|---|

| Numru tal-Mudell | 607011 |

| Jissostitwixxi n-Numri tal-Parti | 60-20714-12, 5651-5538, 60-20714-11, 5651-5552, 5651-5541, 60-20714-22, 5651-5540, 60-20714-10, 60-20714-70, 60-20714-92 |

| Serje Valve | 36C |

| Tip ta' Fjuwil | Natural Gas and LP (Liquid Propane) |

| Capacity (BTU/HR @ 1 in. W.C. Pressure Drop) | 280,000 |

| Opening Type | Standard |

| Sistema ta 'Tqabbid | Pilota |

| Numru ta' Stages | 1 |

| Input Fitting Size NPT | 3/4 pulzier |

| Output Fitting Size NPT | 3/4 pulzier |

| Valve Body Length | 4 pulzieri |

| Valve Body Width | 3-3/16 pulzieri |

| Valve Body Height | 5-1/2 pulzieri |

| Kit ta 'Konverżjoni LP | Inkluż |

| Wiring Harness (Recommended) | 45-25204-01 (White-Rodgers F115-0059) |

| Piż tal-oġġett | 2.6 liri |

| Dimensjonijiet tal-Pakkett | 6.1 x 4.7 x 4.6 pulzieri |

| Finish ta 'barra | Metall |

| Tip ta' Konnessjoni tad-Dħul | Pajp Nazzjonali Tapered |

| Numru ta' Portijiet | 2 |

| UPC | 662766341317 |

6. Informazzjoni dwar Garanzija

Specific warranty details for the ProTech 607011 Spark Pilot Furnace Gas Valve are not provided in this manual. Please refer to the product packaging or contact ProTech customer service for warranty terms and conditions.

7. Appoġġ għall-Klijent

For technical assistance, service, or replacement parts, please contact your licensed HVAC professional or the manufacturer directly. Contact information for ProTech customer service is not included in this document.